Isobutanol is an excellent alternative biofuel which has high energy density, low hygroscopicity, lower vapor pressure, and is compatible with existing transportation infrastructure comparing with traditional biofuel ethanol. Except for being used as biofuel, isobutanol also has many industrial applications, such as solvent, paint additives and ink ingredient. It can also be dehydrated to produce butenes, which is a bulk chemical used for production of synthetic rubber. The global demand for isobutanol is about 500,000 tons per year.

Recently, much attention has been raised on engineering microorganisms for isobutanol production. A synthetic pathway for isobutanol production from glucose had been created by combining the branched-chain amino acids synthetic pathway and the Ehrlich pathway with 2-keto-isovalerate serving as a precursor. Isobutanol production was reached in Escherichia coli and other organisms, such as Corynebacterium glutamicum, Synechococcus elongatus and Bacillus subtilis. However, inducible promoters were used during strain engineering. On the other hand, NADPH is the reducing equivalent required for isobutanol production, while the common reducing equivalent under anaerobic condition is NADH. Isobutanol yield was influenced by the cofactor imbalance problem.

Cell factories were constructed for microbial production of isobutanol by Laboratory of microbial metabolic engineering led by Professor ZHANG Xueli at Tianjin Institute of Industrial Biotechnology, Chinese Academy of Sciences. Genetically stable Escherichia coli strains for isobutanol production were obtained by integrating essential genes into chromosome followed by modulating their expression with constitutive regulatory parts. Membrane-bound transhydrogenase PntAB and NAD kinase YfjB were then activated in combination to convert NADH to NADPH for improving isobutanol production.

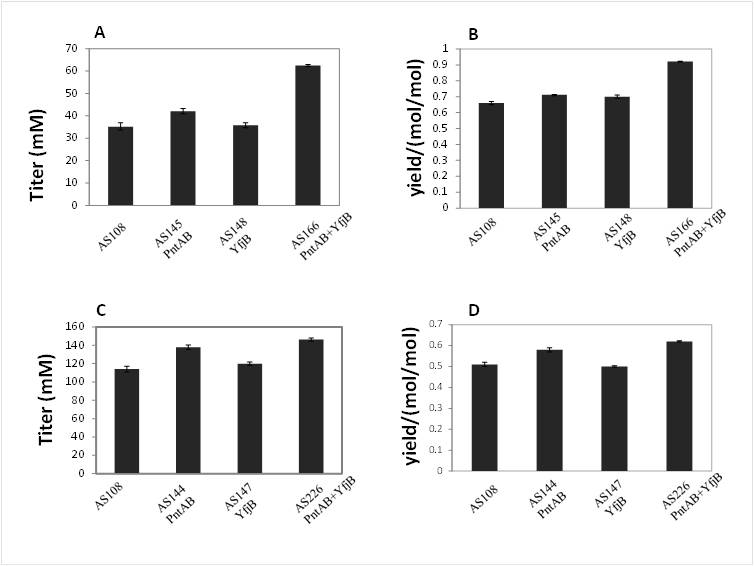

Combinatorial activation of these two enzymes led to 80% and 39% increase of isobutanol titer and yield (Fig. 1A and 1B). A yield of 0.92 mol/mol was obtained under anaerobic condition. The combination also led to 28% and 22% increase of isobutanol titer and yield under aerobic condition (Fig. 1C and 1D), resulting in production of 10.8 g/L isobutanol in 24 h with a yield of 0.62 mol/mol.

This work suggested a synergistic effect of transhydrogenase and NAD kinase on increasing NADPH supply, which will be useful for improving production of target compounds using NADPH as the reducing equivalent within their synthetic pathways.

The study entitled“Activating transhydrogenase and NAD kinase in combination for improving isobutanol production”has been published in Metabolic Engineering . SHI Aiqin , a PhD candidate of TIB, is the first author of this paper. A Chinese patent was also applied (CN201210322624.6). This research was supported by grants from Key Technology R&D program of Tianjin Municipal Science and Technology Commission (10ZCKFSY05800), National Basic Research Program of China (2011CBA00806), and the Technology Foundation for Selected Overseas Chinese Scholar.

Fig. 1 Improvement of isobutanol titer and yield by activating transhydrogenase and NAD kinase. A and B, anaerobic condition; C and D, aerobic condition. (Image by Prof. ZHANG Xueli ’s group)