Succinic acid is an excellentplatform chemical. It has been identified by the U.S. Department of Energy as one of the top 12 building block chemicals which has many applications in food, agricultural, and pharmaceutical industries. Succinic can be used as an intermediary feedstock for production of bulk chemicals, such as 1,4-butanediol, tetrahydrofuran, gamma-butyrolactone, N-methyl-pyrrolidone, 2-pyrrolidon and the excellent biodegradable plastic PBS.

Considerable interest in microbial production of succinate from sugars has emerged during the past decade. Metabolic engineering of this organism which is a minor product during glucose fermentation of Escherichia coli has been widely used for improving succinate production. Its metabolic network has been widely studied so that optimal succinate synthetic pathway with maximum theoretical yield could be easily simulated in genetic engineering. It can use mineral salts as medium thus can reduce production and downstream purification costs.

Xueli Zhang research group of Tianjin Institute of Industrial Biotechnology Chinese Academy of Sciences(TIB,CAS) has carried out in-depth research on the precursor supply of succinic cell factory synthetic pathway.

In E. coli, the uptake and phosphorylation of sugars is carried out by the phosphoenolpyruvate (PEP). Carbohydrate phosphotransferase systems(PTS)of Escherichia coli was usually inactivated to increase PEP supply for succinate production. However, cell growth and glucose utilization rate decrease significantly with PTS inactivation, so we need the other system forglucose transport and metabolism.

In their work,two glucose transport proteins and two glucokinases (Glk) from E. coli and Zymomonas mobilis were recruited in PTS− strains and the impacts on glucose utilization and succinate production were compared.

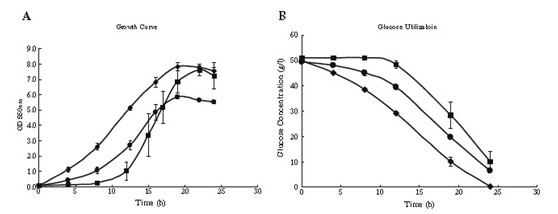

All PTS− strains recruiting Z. mobilis glucose facilitator Glf had higher glucose utilization rates than PTS− strains using E. coli galactose permease (GalP), which was suggested to be caused by higher glucose transport velocity and lower energetic cost of Glf. The highest rate obtained by combinatorial modulation of glf and glk E. coli(2.13 g/L•h) was 81 % higher than the wild-type E. coli and 30 % higher than the highest rate obtained by combinatorial modulation of galP and glk E. coli. On the other hand, although glucokinase activities increased after replacing E. coli Glk with isoenzyme of Z. mobilis, glucose utilization rate decreased to 0.58 g/L•h, which was assumed due to tight regulation of Z. mobilis Glk by energy status of the cells. (Figure 1)

Fig. 1: Comparison of cell growth and glucose utilization of E. coli strains ATCC 8739, GalP93-EcGlk37, and Glf12-EcGlk12. A Growth curve. B Glucose utilization. Square represents ATCC 8739. Circle represents GalP93-EcGlk37. Diamond represents Glf12-EcGlk12

For succinate production, using GalP led to a 20 % increase in succinate productivity, while recruiting Glf led to a 41 % increase. These efficient alternative glucose utilization pathways obtained in their research work can also be used for production of many other PEP-derived chemicals, such as malate, fumarate, and aromatic compounds.

Jinlei Tang from Tianjin University of Science and Technology and Dr. Xinna Zhu from TIB,CAS are the first author for the research paper.Related studies have been published online in Applied Microbiology Biotechnology. This research was supported by grants from the Knowledge Innovation Project of the Chinese Academy of Sciences(KSCX2-EW-G-2), the National Basic Research Program of China (2011CBA00806) and the National High Technology Research and Development Program of China (2011AA02A203).

Link:http://www.springerlink.com/content/wp10h60026406734/