Beta-carotene belongs to carotenoids family, which has lots of applications in pharmaceuticals, neutraceuticals, cosmetics and food industries. The global demand for β-carotene is about 1,000 tons per year. There are two methods for β-carotene production: chemical synthesis and microbial fermentation. Currently, 90% commercialized β-carotene is produced through chemical synthesis. However, its production by microbial fermentation had increased interests and will have great industrialization potential because the feedstock is renewable and the production process is environmental friendly.

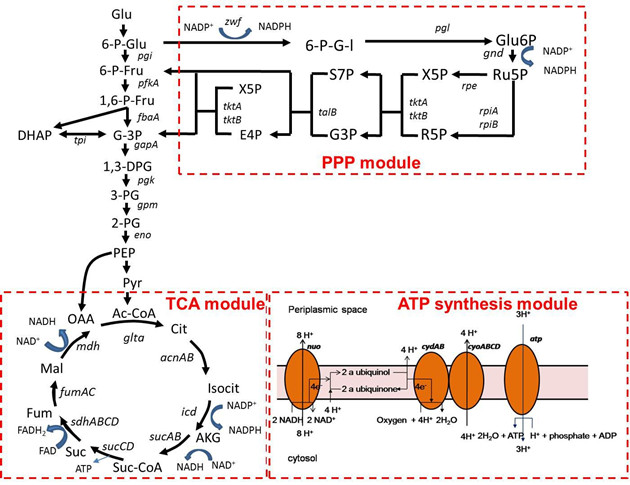

Cell factories were constructed for microbial production of β-carotene by Laboratory of microbial metabolic engineering led by Professor ZHANG Xueli at Tianjin Institute of Industrial Biotechnology, Chinese Academy of Sciences. Through combined engineering of MEP, β-carotene synthesis, TCA, pentose phosphate and ATP synthesis modules, a genetically stable Escherichia coli strain was obtained which exhibited 74-fold yield increase over the wild type. This strain produced 2.1 g/L β-carotene with a yield of 60 mg/g. To the best of our knowledge, this was the highest β-carotene titer and yield obtained for engineered E. coli.

This work suggested that energy and reducing equivalent supplies are key factors for terpenoids synthesis, which will be useful for improving production of terpenoids compounds.

The work entitled “Engineering central metabolic modules of Escherichia coli for improving β-carotene production” has been published in Metabolic Engineering. ZHAO Jing (a graduate student trained by TIB and Tianjin University of Science & Technology in combination) and LI Qingyan (a research associate of TIB) are co-first authors of this paper. A Chinese patent was also applied (CN 201310039787.8). This research was supported by grants from the National Basic Research Program of China (2011CBA00806) and Tianjin Key Technology R&D program of Tianjin Municipal Science and Technology Commission.

Combined engineering of ATP synthesis, TCA and pentose phosphate modules

(Image by Prof. ZHANG Xueli’s group)