The terpenoids sometimes called isoprenoids, are a large and diverse class of naturally occurring organic chemicals similar to terpenes, derived from five-carbon isoprene units assembled and modified in thousands of ways.. The amount of Terpenoids is more than 50000 kinds,and many of them are bioactive components such as monoterpene (menthacamphor, Linalool), sesquiterpene(artemisine,nootkatone),diterpene(taxol,tanshinoneⅡA,ginkgolides),triterpane(ginsenoside, notoginsenoside, glycyrrhizin), polyterpene(carotene), terpenoidalkaloid (dendrobine, erythricine, aconitine, reserpine) and so on.

Terpenoids represent a diverse class of molecules with important medicinal and industrial properties, most of which are synthesized by plants. The terpenoids from medicinal plant sources have great potential applications and the market prospect, especially diterpenoid compounds (TanshinoneⅡA, Triptolide, Oridonin, Paclitaxel) and triterpenoid(ginseng saponins Rh2, ginseng saponins Rg3).

Tanshinones are a group of active diterpenoids found in Chinese medicinal herb Salvia miltiorrhizha Bunge, which exhibit diverse pharmacological activities, including antibacterial, antioxidant, neuroprotective, cardioprotective, and antitumor effects. Tanshinones are a mixture of chemicals, mainly including dihydrotanshinone I, tanshinone I, tanshinone IIA, and cryptotanshinone.

However, terpenoids often accumulate in low content in their native hosts. Because of their complex structures, chemical synthesis of these compounds is inherently difficult and low yield.

At present, there are 3 mainly methods to product the erpenoids: plant extraction, chemical synthesis and microbial fermentation. The content of terpenoids in plants is usually low. Moreover, the extraction from wild plant resources usually destroy the structure. And the chemical synthesis process is high energy consumption and pollution. In contrast, the production is by microbial fermentation that in addition to the unlimited raw materials is the green and clean process.

Metabolic engineering of microorganisms is an alternative and attractive route for production of these valuable compounds. This strategy has been used to engineer model microorganisms for successful production of many terpenoids and important precursors in their biosynthesis pathways. The development of synthetic biology provides the powerful support to realize the microbial fermentation to produce medical terpenoids with effective component.

XueLi Zhang research group of Tianjin Institute of Industrial Biotechnology Chinese Academy of Sciences and Luqi Huang research group of Institute of Chinese Medica Medica, Chinese Academy of Chinese Medical Science cooperated in the research of artificial cell synthesis medicinal terpenoids.

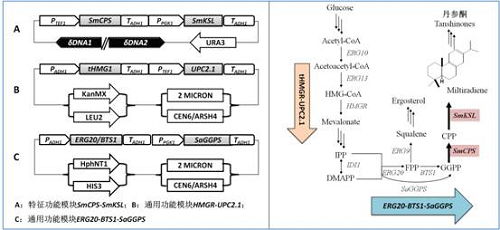

At present, they studies on the identification of terpenoids synthesis methods, the anticodon optimizing expression of different source of the genes, the standard assembly and accurate control of synthetic way and optimizing microbial fermentation. The function module (tHMGR-upc2.1 and ERG20-BTS1-SaGGPS), a combined regulation saccharomyces cerevisiae terpenoids synthetic way, has been developed facing the problem how the coupling between yeast biology and synthetic biology is advancing the use of S. cerevisiae as a microbial host for the construction of secondary metabolic pathways. Through the reasonable collocation improved the ability of artificial yeast cell synthesized diterpene and triterpenoid.

They use Saccharomyces cerevisiae as the host and over-express some genes which convert the universal diterpenoid precursor geranylgeranyl diphosphate (GGPP) to miltiradiene (an important intermediate of the tanshinones synthetic pathway) to improve the production of titer. In each over-express experiments, the yield of titer is not so high although it is higher than before. At last, by combining over-expression of tHMGR-upc2.1 and ERG20-BTS1-SaGGPS genes that have a synergetic effects on miltiradiene production, the yield of titer increase to 61.8?mg/L. (Figure)

Finally, fed-batch fermentation was performed, and 488 mg/L miltiradiene was produced,and the production of squalene output reached 852 mg/L. The engineered yeast strains in they work provide a basis for creating an alternative way for production of tanshinones in place of extraction from plant sources.

In conclusion, the engineered yeast strains provided a basis for creating an alternative way for production of tanshinones in place of extraction from plant sources. Although large amount of miltiradiene was produced, antibiotics were added to keep stabilities of the episomal plasmids, which was not feasible for large-scale industrial production. Integration strategies will be used further to over-express essential genes to improve supplies of isoprenoid precursors to obtain genetically stable yeast strains for efficient miltiradiene production.

This research was supported by grants from the National Basic Research Program of China (2011CBA00806), the Knowledge Innovation Project of the Chinese Academy of Sciences (KSCX2-EW-G-2), and National Natural Science Foundation of China (NO. 81072990).

Link:http://onlinelibrary.wiley.com/doi/10.1002/bit.24547/abstract